Direct Thermal vs Thermal Transfer: Which One Fits Your Needs?

Published: December 15, 2025

FAQ: How do I integrate my Barcode printer into my network?

Answer: All Barcode printers have the option to upgrade into Ethernet modules to connect to any network, Wireless, and LAN. However, the Industrial Printer normally comes with an Ethernet module included in the MLB

Choosing the right label printing method can feel confusing at first, but it doesn’t have to be. In most cases, the decision simply comes down to how long you need your labels to last and where they’ll be used.

To help you decide without technical jargon, here’s a clear and beginner-friendly guide to the two most common printing methods: Direct Thermal and Thermal Transfer.

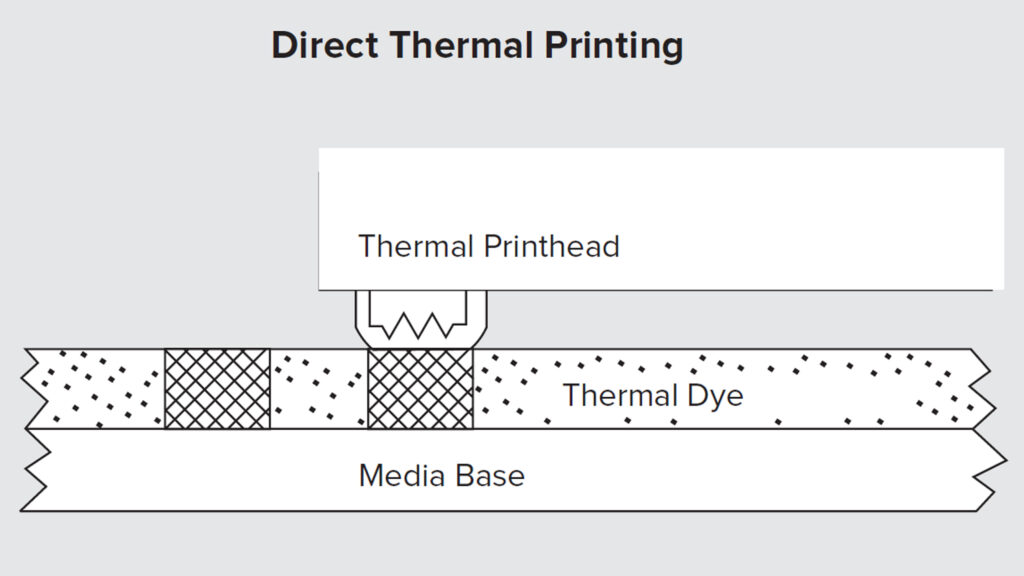

Direct Thermal: Fast & Fuss-Free

Direct Thermal printers use heat-sensitive labels. No ribbons, no extras — plug, print, done.

Where it works best:

- Shipping labels

- Receipts

Food labels (short shelf life)

Why people like it:

- Fewer supplies to manage

- Faster setup

Affordable for high-volume printing

Keep in mind:

The prints fade over time, especially when exposed to heat, sunlight, or friction.

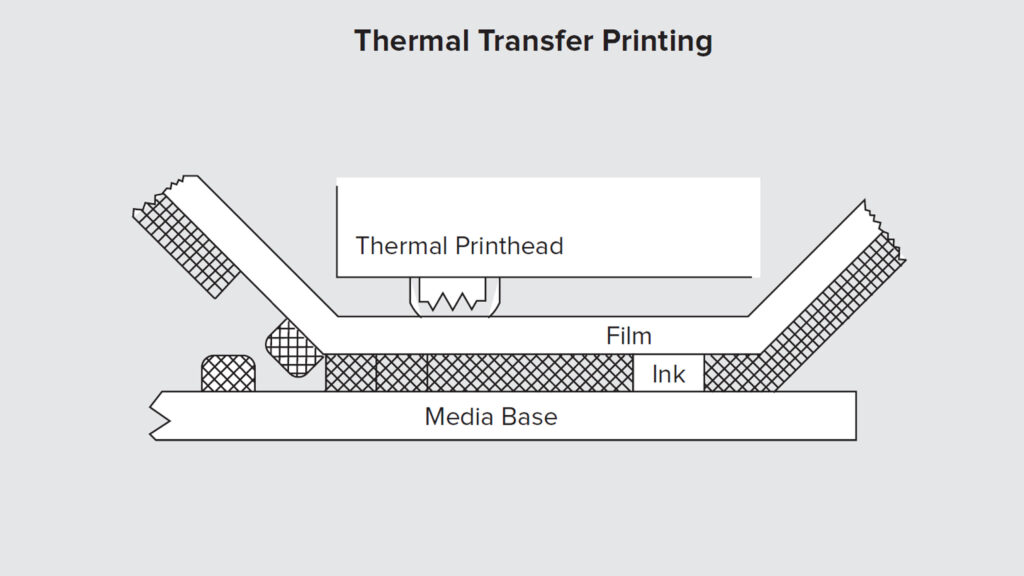

Thermal Transfer: Durable & Long-Lasting

Thermal Transfer uses a ribbon to create sharper, longer-lasting prints that stay readable.

Best for:

- Product labels

- Warehouse inventory

- Healthcare & lab labels

Outdoor or chemical-exposed environments

Why people choose it:

- High durability

- Works on more materials (paper, synthetic, film)

Reliable scanning even after months or years

Note:

You’ll need ribbons, but you gain a better label lifespan.